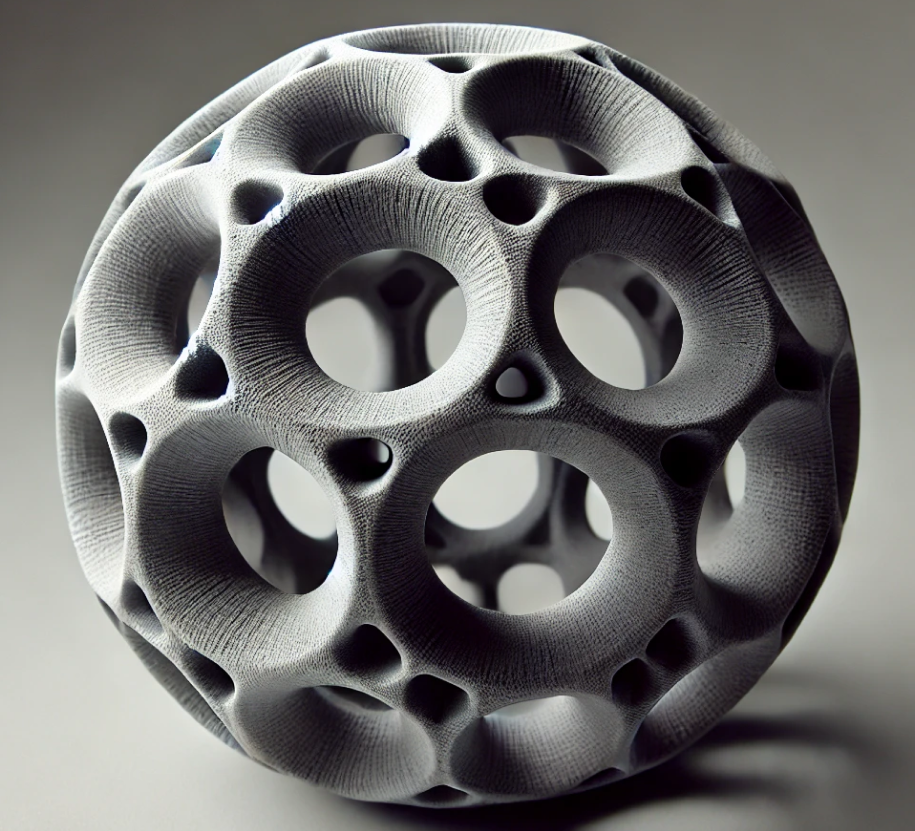

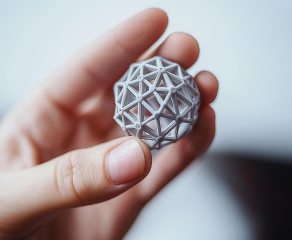

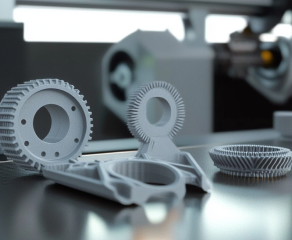

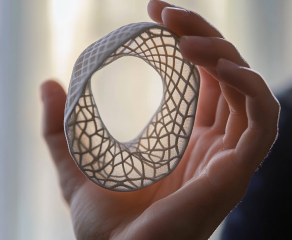

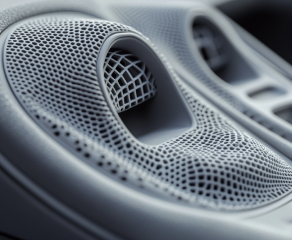

MJF Capabilities

Our Multi Jet Fusion 3D Printing Capability

Explore our advanced MJF 3D printing capabilities, delivering high-quality, durable parts with fine details and smooth surface finishes. From functional prototypes to end-use products, we ensure output tailored to your exact specifications.

-

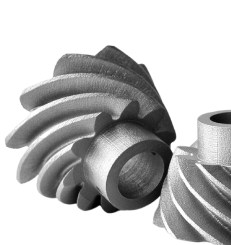

High-Speed Production

-

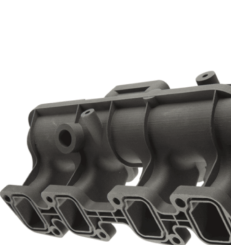

Excellent Mechanical Properties

-

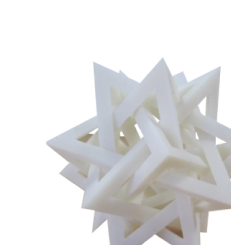

Fine Detail and Smooth Finishes