-

How it works

-

Industries

-

Services

-

Material

-

Company

-

Resources

Industries

Industries

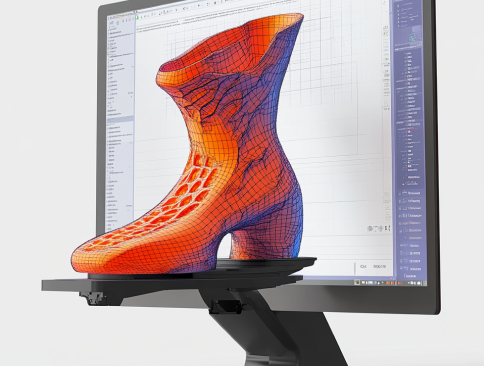

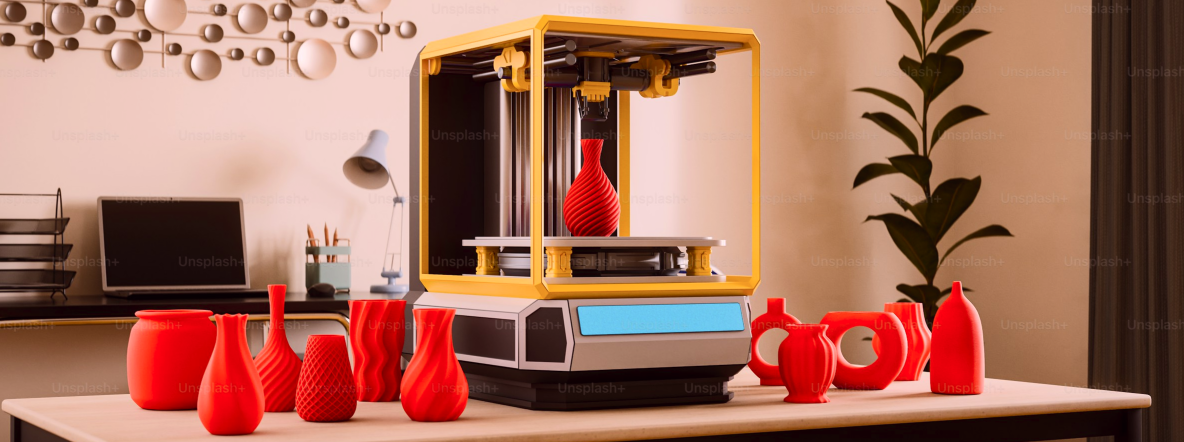

Start by uploading your 3D model file in formats like STL or CAD to our user-friendly platform. Our system quickly analyzes the file’s geometry and details to generate an accurate blueprint for production. Our system will analyze the file and provide you with a near-instant quotation.This efficient process ensures that you're ready to receive your quote within minutes and potential lead times before moving forward.

Once your file is uploaded, receive a real-time, instant quotation based on the complexity, material, and quantity of your order. Our system also factors in the technology, whether it's FDM, SLA, SLS, or MJF, and materials to deliver a precise and competitive price tailored to your project's needs. Our advanced system connects you with the closest manufacturing facility equipped to produce your part, optimizing the speed and cost-effectiveness of the process. You can adjust parameters and confirm the order with just a few clicks.

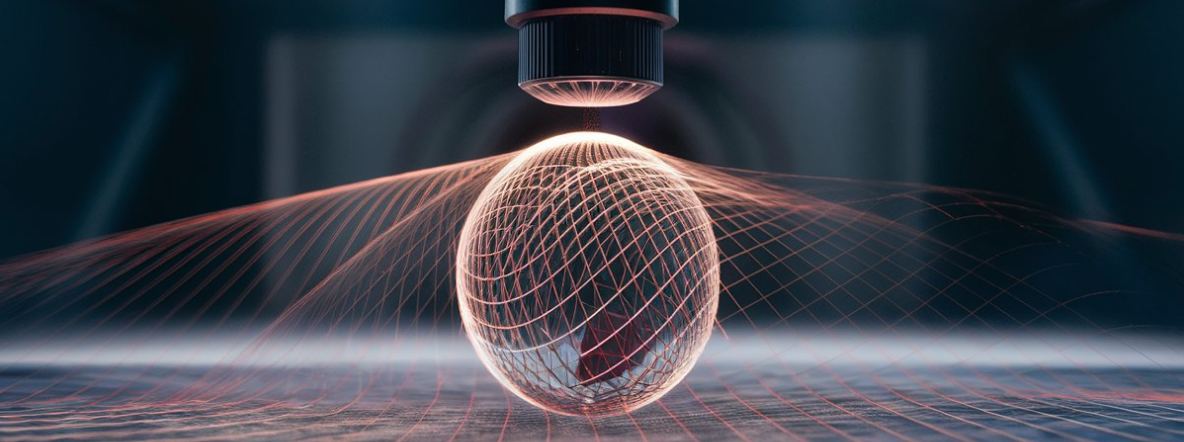

After order confirmation, your part moves to production at the nearest manufacturing facility. Each part undergoes a strict production cycle, tailored to meet your specifications. After production, the parts undergo a rigorous quality check, ensuring dimensional accuracy, surface finish, and structural integrity. This step ensures that your parts meet the highest standards before being prepared for delivery.

Once the parts pass our strict quality checks, they are securely packaged and prepared for shipment. We manage all aspects of logistics, ensuring your order is safely delivered to your specified address.Our platform offers live tracking so you can monitor your shipment in real-time, providing peace of mind and ensuring timely delivery right to your doorstep.

Start your 3D printing process by uploading your STL or CAD file to our platform. The STL format serves as the digital blueprint, containing all essential geometric details necessary for production. Once uploaded, our advanced system analyzes your design and instantly provides an accurate quotation. The process is fast, reliable, and ensures you can review both costs and delivery times before proceeding. By streamlining the 3D printing quotation process, we make it easier for you to plan your project from design to delivery.

For 3D printing, solid CAD models with watertight geometry are essential. STL files are the most widely used format, converting the design into a mesh that defines the surface geometry. To avoid print failures, ensure your model features manifold geometry, where every edge connects to two faces. Simplified designs not only reduce errors but also speed up the printing process, especially when using low-end printers. Additionally, scaling your model correctly ensures the printed part matches the intended dimensions. Always verify the measurements and geometry before exporting the file for printing.

There are several CAD software tools that are widely used and fully compatible with 3D printing workflows. Here’s an overview of popular ones:

| AutoCAD: A versatile software known for creating 2D and 3D designs. It can export files in STL format, making it suitable for 3D printing, especially for users familiar with architectural or mechanical designs. |

| Fusion 360: Developed by Autodesk, Fusion 360 is an integrated CAD, CAM, and CAE platform. It is highly regarded for its ability to create parametric models and is fully compatible with 3D printing through its direct STL export features. Its cloud-based collaboration features make it particularly suitable for team-based projects. |

| SolidWorks: SolidWorks is a powerful CAD software known for its extensive use in engineering and manufacturing. It supports complex surface modeling, solid geometry, and assemblies, and has integrated tools to export in 3D printing-friendly formats like STL. It’s popular for industrial-grade design work. |

| TinkerCAD: A user-friendly, browser-based option, TinkerCAD is great for beginners or hobbyists. It allows users to quickly create simple 3D models, which can easily be exported in STL format for 3D printing. |

| Blender: Though traditionally used for animation and visual effects, Blender has strong 3D modeling capabilities and can be used to create detailed models for 3D printing. With its extensive support for various file formats, including STL, it’s ideal for artistic and creative projects. |

| Rhino: Known for its ability to create freeform surfaces, Rhino (Rhinoceros) is often used for 3D modeling in product design and architecture. It’s fully compatible with 3D printing through its STL export options and is favored by designers working on complex organic shapes. |

| SketchUp: An intuitive and easy-to-learn software, SketchUp is commonly used for architectural designs but also works well for simpler 3D printing projects. It can export models in STL format for printing. |

| Onshape: A cloud-based CAD solution, Onshape allows for real-time collaboration and is well-suited for 3D printing, especially for teams that need to work on designs simultaneously. It supports STL export for printing. |

When it comes to 3D printing, selecting the right technology, material, and infill percentage is crucial for achieving optimal results. Each of these factors influences the cost, durability, and appearance of your final product. Here’s a guide to help you make the best choices for your projects.

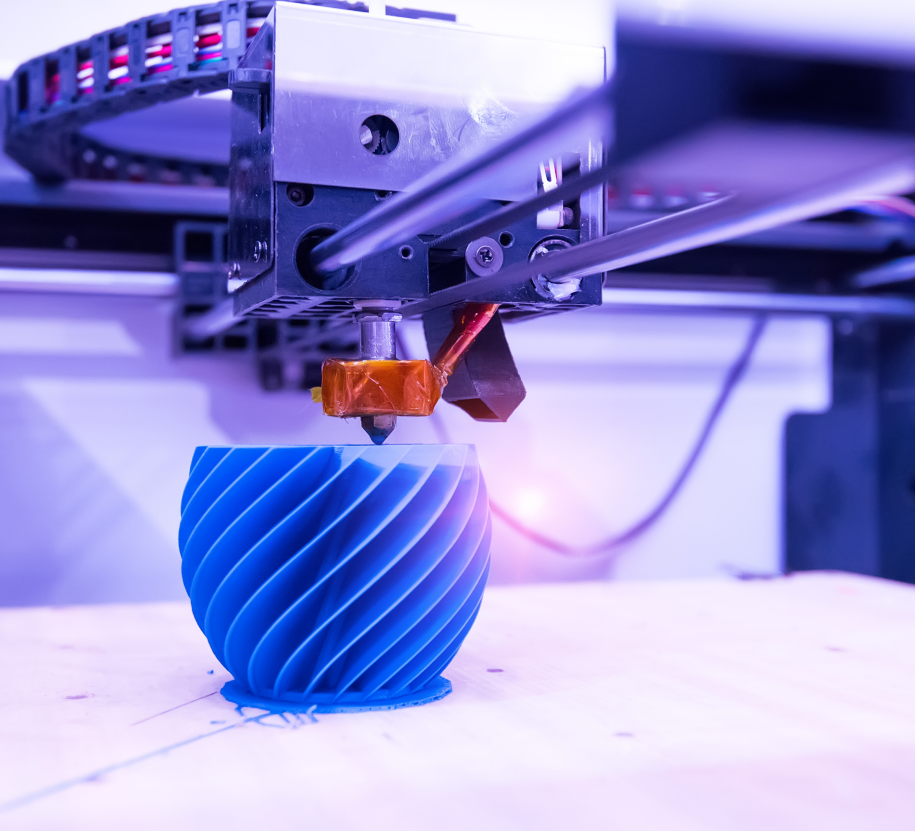

Choosing the right 3D printing technology depends on the purpose of your project. The most commonly used technologies include:

| Technology |

|---|

FDM (Fused Deposition Modeling):Best for prototypes and functional parts, this method is cost-effective and offers a variety of material choices. |

SLA (Stereolithography): Known for its high-resolution finishes, SLA is ideal for detailed, intricate designs like jewelry and models. |

SLS (Selective Laser Sintering):This technology is perfect for producing durable, strong parts, often used in automotive and aerospace industries. |

MJF (Multi Jet Fusion):Offers smooth surface finishes and fine detail, making it suitable for both functional prototypes and end-use parts. |

DMLS (Direct Metal Laser Sintering):Ideal for creating strong metal parts with complex geometries, DMLS is used in high-end applications like aerospace and medical for durable, precise components. |

PolyJet: Best for high-detail prototypes and multi-material parts, PolyJet produces smooth finishes and can combine different materials and colors in a single print, perfect for detailed models. |

The right material plays a critical role in determining the strength, flexibility, and heat resistance of your printed part. Common 3D printing materials include:

Infill percentage refers to how solid the interior of your 3D print is. Higher infill results in a stronger part but increases material use and cost, while lower infill reduces weight and cost but can compromise strength. The common infill percentages are:

Selecting the right infill percentage helps balance between strength and cost-effectiveness.

Our pricing is calculated based on several factors:

When calculating 3D printing costs, the machine time is a significant factor. This cost is calculated by multiplying the hourly rate of the 3D printer by the total time it takes to print a part.

Machine Time Cost = Hourly rate of the printer × Print time (in hours)

A 3D printer with an hourly rate of ₹500 prints a part in 2 hours.

The total Machine Time Cost = ₹50/hour × 2 hours = ₹100.

After the printing process, some parts may require additional finishing work, which is where post-processing costs come into play. These costs are based on labor rates and the time required for tasks like sanding, cleaning, polishing, or curing.

Post-Processing Cost = Labor rate per hour × Time for post-processing (in hours)

If the labor rate is ₹100/hour and the post-processing takes 1.5 hours, the total Post-Processing Cost = ₹100/hour × 1.5 hours = ₹150.

We prioritize the security and confidentiality of your designs. All client files and sensitive information are stored in an encrypted database that ensures data protection throughout the entire 3D printing process. Our platform also supports Non-Disclosure Agreements (NDAs), safeguarding your intellectual property from unauthorized access or disclosure. Whether it's protecting proprietary designs or critical manufacturing details, you can trust our commitment to maintaining the highest standards of data security and confidentiality.

At IamRapid, we ensure that every product we manufacture is built to meet stringent quality standards, no matter the scale or complexity of the project. From the moment you place an order, our team follows a structured, precise manufacturing workflow designed to guarantee accuracy, precision, and superior quality in every part produced. Using advanced 3D printing technologies, we create not only durable prototypes but also fully functional, end-use parts for a wide variety of industries, including automotive, aerospace, medical, and consumer electronics.

By leveraging state-of-the-art machinery and the latest additive manufacturing techniques, we are able to provide customized solutions that are tailored to the specific needs of our clients. From the early stages of rapid prototyping to final product manufacturing, our commitment to quality, efficiency, and customer satisfaction ensures you receive a product that meets all your expectations.

ard Inspection Report provides a detailed analysis of each part's dimensional accuracy, surface finish, and structural integrity. We perform stringent checks to ensure that all components conform to your project specifications, whether you require precise mechanical parts or finely detailed prototypes.

Our inspection process helps identify potential issues early, allowing for any necessary adjustments to be made before final delivery. This process ensures that your parts are manufactured to the highest standards, suitable for their intended use across industries like aerospace, medical devices, robotics, and consumer electronics.

We take meticulous care in the handover of all products to ensure that your 3D printed parts are delivered safely and securely, regardless of their destination. Our attention to detail extends from production to packaging and shipment, ensuring that every step is handled with professionalism and precision.

Our standard packaging process is designed to protect your 3D printed parts from damage during transit. Each item is carefully packed using high-quality protective materials, ensuring that even the most delicate or complex components are secured properly. Whether you are ordering small-scale prototypes or larger end-use parts, we use industry-standard methods that prevent scratches, dents, or other potential damage during shipping.

Our packaging solutions are designed to maintain the integrity of your product, regardless of the size, shape, or material used in the manufacturing process. By prioritizing the safety of your parts during transportation, we ensure that your products arrive in perfect condition.

IamRapid offers global shipping solutions to ensure that your products reach you, no matter where you are located. We partner with trusted logistics providers to offer timely and reliable shipping across North America, Europe, Asia, and beyond. Our platform provides real-time tracking of your shipment, allowing you to monitor the status of your order from production to delivery.

With flexible shipping options and expedited services available, we ensure your products are delivered as quickly as possible, no matter the destination.