No Material Found

Currently, we do not have any materials for the applied filters.

PLA (Polylactic Acid)

Pros: Easy to Print

Applications: Low Heat Resistance

- More:

-

Pros: Easy to Print

-

Cons: Low Heat Resistance

-

Applications: Education Applications , Prototyping Applications

Available color:

Available color:

- Black

- White

- Red

- Blue

- Green

- Yellow

- Transparent

- Metallic

Price:

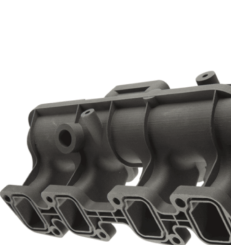

ABS (Acrylonitrile Butadiene Styrene)

Pros: High Impact Resistance

Applications: Warping Tendency

- More:

-

Pros: High Impact Resistance

-

Cons: Warping Tendency

-

Applications: Automotive Applications , Consumer Electronics Applications

Available color:

Available color:

- Black

- White

- Natural (off-white)

- Red

- Blue

- Green

- Yellow

- Gray

Price:

TPU 95A (Thermoplastic Polyurethane)

Pros: Flexible and Elastic

Applications: Difficult to Print

- More:

-

Pros: Flexible and Elastic

-

Cons: Difficult to Print

-

Applications: Automotive Applications , Consumer Electronics Applications

Available color:

Available color:

- Black

- White

- Natural (Translucent)

- Red

- Blue

- Green

- Yellow

Price:

PETG (Polyethylene Terephthalate Glycol)

Pros: Strong and Durable

Applications: Sensitive to Moisture Absorption

- More:

-

Pros: Strong and Durable

-

Cons: Sensitive to Moisture Absorption

-

Applications: Medical Devices Applications , Automotive Applications

Available color:

Available color:

- Clear (Transparent)

- Black

- White

- Red

- Blue

- Green

- Orange

Price:

Nylon (Polyamide)

Pros: High Mechanical Strength

Applications: Hygroscopic (Moisture Absorption)

- More:

-

Pros: High Mechanical Strength

-

Cons: Hygroscopic (Moisture Absorption)

-

Applications: Automotive Applications , Industrial Machinery Applications

Available color:

Available color:

- Natural (off-white)

- Natural (Translucent)

- Black

- White

Price:

Tough PLA

Pros: High Impact Resistance

Applications: Lower Heat Resistance Compared to ABS

- More:

-

Pros: High Impact Resistance

-

Cons: Lower Heat Resistance Compared to ABS

-

Applications: Automotive Applications , Consumer Products Applications

Available color:

Available color:

- Black

- White

- Red

- Blue

- Green

- Gray

Price:

Lightweight PLA

Pros: Low Density / Lightweight

Applications: Requires Careful Temperature Control

- More:

-

Pros: Low Density / Lightweight

-

Cons: Requires Careful Temperature Control

-

Applications: Aerospace Modeling Applications , Automotive Modeling Applications

Available color:

Available color:

- White

- Natural Shades

Price:

Conductive PLA

Pros: Electrically Conductive

Applications: Limited Conductivity

- More:

-

Pros: Electrically Conductive

-

Cons: Limited Conductivity

-

Applications: Electronics Applications , Education Applications

Available color:

Available color:

- Black

Price:

ASA (Acrylonitrile Styrene Acrylate)

Pros: UV Resistance

Applications: Warping Tendency

- More:

-

Pros: UV Resistance

-

Cons: Warping Tendency

-

Applications: Automotive Applications , Construction Applications

Available color:

Available color:

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

Price:

Carbon Fiber PETG Composite

Pros: High Stiffness and Rigidity

Applications: Abrasive to Nozzles

- More:

-

Pros: High Stiffness and Rigidity

-

Cons: Abrasive to Nozzles

-

Applications: Automotive Applications , Aerospace Applications

Available color:

Available color:

- Black

Price:

Carbon Fiber PLA Composite

Pros: High Stiffness and Strength

Applications: Abrasive to Nozzles

- More:

-

Pros: High Stiffness and Strength

-

Cons: Abrasive to Nozzles

-

Applications: Automotive Applications , Aerospace Applications

Available color:

Available color:

- Black

Price:

ULTEM™ (Polyetherimide) Flame Retardant

Pros: Flame Retardant (UL94 V-0)

Applications: Difficult to Print

- More:

-

Pros: Flame Retardant (UL94 V-0)

-

Cons: Difficult to Print

-

Applications: Aerospace Applications , Automotive Applications

Available color:

Available color:

- Amber

- Black

Price:

Wood Filled PLA

Pros: Wood-Like Appearance and Texture

Applications: Abrasive to Nozzles

- More:

-

Pros: Wood-Like Appearance and Texture

-

Cons: Abrasive to Nozzles

-

Applications: Art and Design Applications , Architecture Applications

Available color:

Available color:

- Wood Tones

- Light Medium

- Dark Wood

Price:

HIPS (High Impact Polystyrene)

Pros: High Impact Resistance

Applications: Susceptible to Warping

- More:

-

Pros: High Impact Resistance

-

Cons: Susceptible to Warping

-

Applications: Product Design and Development Applications , Consumer Good Applications

Available color:

Available color:

- White

- Black

- Natural

Price:

Filter

Tailored 3D printing solutions to meet specific client needs

Find your queries

Frequently Asked Question(FAQ)

- General Information

- Material Properties and Applications

- Post-Processing

- Sustainability and Environmental Impact

- Advanced Materials

-

What types of materials are available for 3D printing on

your platform?

- Our materials page showcases a wide range of 3D printing materials, including standard plastics (like PLA, ABS, and PETG), engineering-grade options (such as Nylon, Carbon Fiber composites, and TPU), advanced resins for SLA and DLP printing, and high-performance metals for DMLS. Each material is tailored to specific applications, providing options for everything from functional prototypes to final end-use parts.

-

How do I use the material filters to find the right

option for my project?

- The material filters are designed to make it easy to narrow down your choices based on specific properties and requirements. You can filter materials by attributes like strength, flexibility, heat resistance, surface finish, and chemical resistance. Simply check the boxes for the characteristics you need, and the page will automatically update to show materials that match your criteria.

-

What is the difference between standard and

engineering-grade materials?

- Standard materials, such as PLA and ABS, are cost-effective and suitable for general-purpose applications like prototypes and models. Engineering-grade materials, on the other hand, offer enhanced mechanical properties, such as higher strength, impact resistance, or heat tolerance. These materials are ideal for industrial and functional parts that must withstand demanding conditions or heavy use.

-

Can I compare multiple materials side by side using the

filters?

- Yes, our platform allows you to compare multiple materials side by side. Once you have selected filters that meet your needs, you can view a detailed comparison of each material's properties, such as tensile strength, elongation at break, and thermal resistance. This feature helps you make an informed decision and choose the material that best suits your project requirements.

-

Are there materials that are only compatible with

specific 3D printing technologies?

- Yes, certain materials are designed for use with specific 3D printing technologies. For example, resins are used with SLA and DLP printers, while powder-based materials like Nylon PA12 are used in SLS and MJF printers. The material filters on our page provide information on technology compatibility, so you can easily select materials that work with your preferred printing method.

-

How can I determine which material has the right strength

for my application?

- To choose a material with the appropriate strength, consider the mechanical properties listed on the materials page, such as tensile strength, impact resistance, and flexural modulus. For parts that need to withstand heavy loads or impact, engineering-grade materials like Carbon Fiber composites or Nylon are ideal. The material filters allow you to search specifically for high-strength options to suit your needs.

-

What materials are best for flexible parts or

components?

- For flexible parts, materials like TPU and TPE are excellent choices. These thermoplastic elastomers offer high elongation at break and a rubber-like feel, making them suitable for gaskets, seals, and wearables. You can use the flexibility filter to view all available options for flexible materials and compare their properties to find the best fit for your project.

-

Are there materials that are heat-resistant and suitable

for high-temperature applications?

- Yes, we offer a variety of heat-resistant materials that can withstand high temperatures without deforming. Options like PEEK, PEI (Ultem), and certain high-performance resins are designed for use in environments with elevated heat. Use the heat resistance filter to find materials that meet your temperature requirements, and check their thermal properties for specific limits.

-

What materials are suitable for parts that will be

exposed to chemicals or moisture?

- For chemical-resistant parts, materials like PETG, Polypropylene, and specific engineering resins are ideal. These materials offer excellent resistance to chemicals, oils, and moisture, making them suitable for industrial applications, outdoor use, and environments where exposure to harsh substances is expected. The chemical resistance filter can help you identify these options quickly.

-

Can I use materials that are both strong and

lightweight?

- Absolutely. Materials like Carbon Fiber Nylon and Aluminum-Filled composites provide a great balance of strength and weight. These composites are reinforced with fibers or fillers to increase mechanical performance while keeping the overall weight low. This makes them perfect for automotive, aerospace, and sporting goods applications. Use the strength and weight filters to find these specialized materials.

-

Do different materials require different post-processing

methods?

- Yes, each material may require unique post-processing techniques to achieve the desired surface finish and mechanical properties. For example, SLA resins may need UV curing to fully harden, while FDM prints might require sanding, painting, or chemical smoothing for a polished appearance. Our materials page provides information on recommended post-processing methods for each material.

-

How can I improve the surface finish of my 3D printed

part?

- Improving the surface finish depends on the material and the desired outcome. Options include sanding, polishing, vapor smoothing, and applying a coating or primer. For example, ABS parts can be smoothed using acetone vapor, while resin prints may benefit from a clear coat. Check the post-processing guidelines for your chosen material to learn the best practices.

-

Are there materials that come with built-in finishing

options, like colors or textures?

- Yes, some materials are available in various colors and textures that reduce the need for additional finishing. For instance, PolyJet materials can be printed in full color, and certain filaments come in matte or glossy finishes. Additionally, composites like Wood-Filled PLA have a natural wood-like texture that can be sanded and stained for a realistic appearance.

-

Can I paint or dye my 3D printed parts?

- Most 3D printed parts can be painted or dyed, but the process may vary depending on the material. PLA, ABS, and resins are easy to paint with acrylic paints, while Nylon may require special dyes to achieve vibrant colors. Surface preparation, such as sanding and priming, is crucial to ensure good adhesion and a smooth finish. Consult the material's post-processing recommendations for the best results.

-

What should I consider when polishing metal 3D printed

parts?

- Polishing metal parts, such as those printed with DMLS or SLM technology, requires careful handling and specialized equipment. Techniques like tumbling, sanding, and electro-polishing can achieve a mirror-like finish. Be mindful of the material's hardness and wear resistance, as improper polishing can damage the part. Always follow safety guidelines when working with metal powders and machinery.

-

Are there eco-friendly or biodegradable 3D printing

materials available?

- Yes, we offer several eco-friendly and biodegradable materials, such as PLA, which is derived from renewable resources like cornstarch. PLA is compostable under industrial conditions and is an excellent choice for environmentally conscious projects. Additionally, recycled filaments and resins made from sustainable sources are available. Use the sustainability filter to find these materials.

-

How can I reduce waste when using 3D printing

materials?

- Reducing waste can be achieved by optimizing your 3D model to use less material, recycling failed prints, and using support structures sparingly. Many 3D printing services also offer recycling programs for used materials and failed parts. Choosing materials with high reusability, such as MJF Nylon PA12, can further minimize waste and environmental impact.

-

What are the environmental impacts of using resin-based

3D printing??

- Resin-based 3D printing, such as SLA, can have environmental impacts due to the chemical composition of the resins. Unused or waste resin must be handled and disposed of properly to avoid environmental harm. Some manufacturers are developing eco-friendly resins with lower toxicity and biodegradable properties. Always follow disposal guidelines for hazardous materials and consider using low-impact resins when possible.

-

Are there materials that are recyclable or made from

recycled content?

- Yes, several materials are recyclable or made from recycled content. Some filament manufacturers produce recycled PLA and PETG, which are made from post-consumer or post-industrial waste. Nylon materials used in SLS and MJF printing often have high reusability rates, reducing material waste. Check the material details to see if recycling or reuse options are available.

-

How do I properly dispose of 3D printing materials?

- Proper disposal of 3D printing materials depends on the type of material. PLA can be composted in industrial facilities, while ABS and other thermoplastics should be recycled if possible. Resin waste must be cured and disposed of as hazardous waste. Always follow local regulations for waste disposal and consider using eco-friendly materials to reduce your environmental footprint.

-

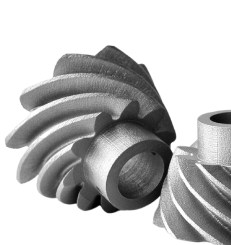

What are composite materials, and when should I use

them?

- Composite materials are made by combining two or more different substances to create a material with enhanced properties. Examples include Carbon Fiber PLA and Wood-Filled PLA. These materials are ideal for applications that require increased strength, reduced weight, or unique aesthetics. Use them for projects where traditional materials may not provide the necessary performance or appearance.

-

How does the layer height affect the properties of 3D

printed materials?

- Layer height impacts both the appearance and mechanical properties of 3D printed parts. Thicker layers increase print speed but may reduce detail and surface smoothness. Conversely, thinner layers provide higher resolution and smoother surfaces but can make the print more time-consuming. Mechanical properties can also be affected, with thicker layers generally resulting in stronger parts along the z-axis.

-

Are there materials that can be used for food-safe

applications?

- Some materials, like certain grades of PETG and FDA-approved resins, are suitable for food-safe applications. However, the printing process itself can introduce contaminants, so additional measures, such as post-processing and applying food-safe coatings, may be necessary. Always check for food safety certifications and follow best practices when creating food-contact parts.

-

What materials are suitable for outdoor use and UV

exposure?

- Materials like ASA, UV-resistant resins, and certain grades of Nylon are well-suited for outdoor use and prolonged UV exposure. These materials are engineered to withstand harsh weather conditions and resist degradation from sunlight. Use the UV resistance filter to find materials specifically designed for outdoor applications.

-

Can I use flexible materials for parts that will

experience repeated stress or movement?

- Yes, flexible materials like TPU and TPE are designed for parts that require repeated stress or movement. These materials have high elongation at break and excellent fatigue resistance, making them suitable for wearable devices, seals, and gaskets. Make sure to select a material with the appropriate Shore hardness for your specific application to ensure durability and performance.

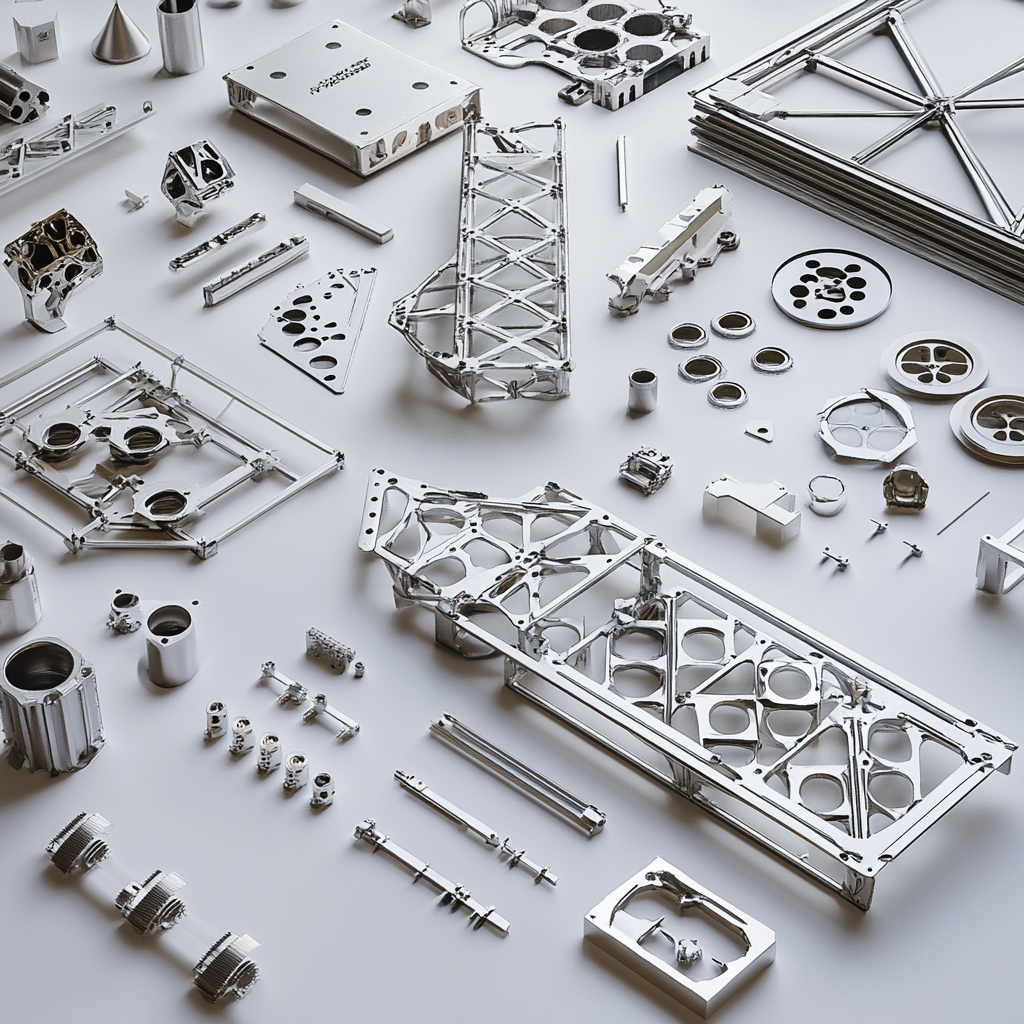

Our Fabrication Services

Our 3D Printing Technologies

Online 3D printing services swiftly delivers high-quality mechanical parts from prototype to batch production across India. Instant quotation and delivery lead times starting from 24 hours.

FDM

Fused Deposition Modeling

-

Fast and affordable prototyping

-

A wide range of materials

-

Short lead times perfect for rapid iterations

SLA

Stereolithography

-

High Detailed prototypes

-

Smooth Surface Finishes

-

Best suited for industries like Healthcare and Jewellery

SLS

Selective Laser Sintering

-

Ideal for batch production

-

No need for support structures

-

Strong, Functional prototypes for end use

PolyJet

Photopolymer Jetting

-

Ultra High resolution

-

Multi-material capabilities

-

Smooth surface finished ideal for realistic prototypes